CNC Router Lines

The Money Maker for nested based manufacturing companiesA CNC Router Line generates significant additional savings in running costs with a small increase in the initial investment for a CNC Router. It takes panel processing to a whole new level - With the addition of an automatic loading and unloading system, there is a huge reduction in material handling. The system will load individual sheets from the sheet rack located behind the machine and lift the sheet into position on the CNC Router bed, ready for processing. When the components are processed they are then pushed onto a conveyor located at the front of the machine, while at the same time loading the next sheet to be processed. CNC Router Lines are ideally suited for small and medium Kitchen and Wardrobe manufacturers. Production becomes a fully automated process with one operator in a continuous cycle. The return in investment with a CNC Router Line com much faster than with a standalone CNC Router. Time is money!

CNC Router Lines - The Money Maker and the ultimate in Lean manufacturing for Panel Processors

With the recent install of a CNC Router Line complete with Manufacturing Software and a Tooling Package we generated savings of 160 hours per week for medium sized Kitchen and Wardrobe manufacturer, reducing their manufacturing costs and giving them the opportunity to increase their sales with the additional capacity available in production.

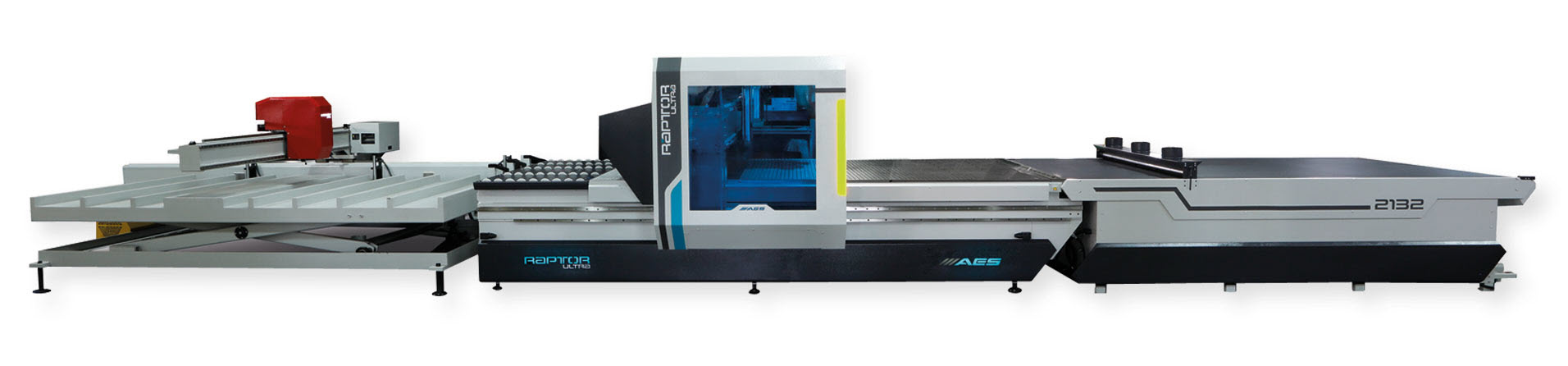

The Machine options - The Extreme Ultra Line and The Raptor Ultra Line

Our CNC Router Lines are available in 2 models – The Extreme and the Raptor. Both models are available in 9 different sizes ranging from the popular 1325 (4’x8’) model up to the large 2157 model with a (7’x18’6” bed). Each model has an extensive range of options available allowing individual machines to be customised to a customer’s specific requirements.